18 Years Factory Low Alloy Heat Resistant Steel Plate - Wear resistant steel plate / impact resistant plate / high temperature resistant plate for construction machine – Huayi

18 Years Factory Low Alloy Heat Resistant Steel Plate - Wear resistant steel plate / impact resistant plate / high temperature resistant plate for construction machine – Huayi Detail:

Product Description

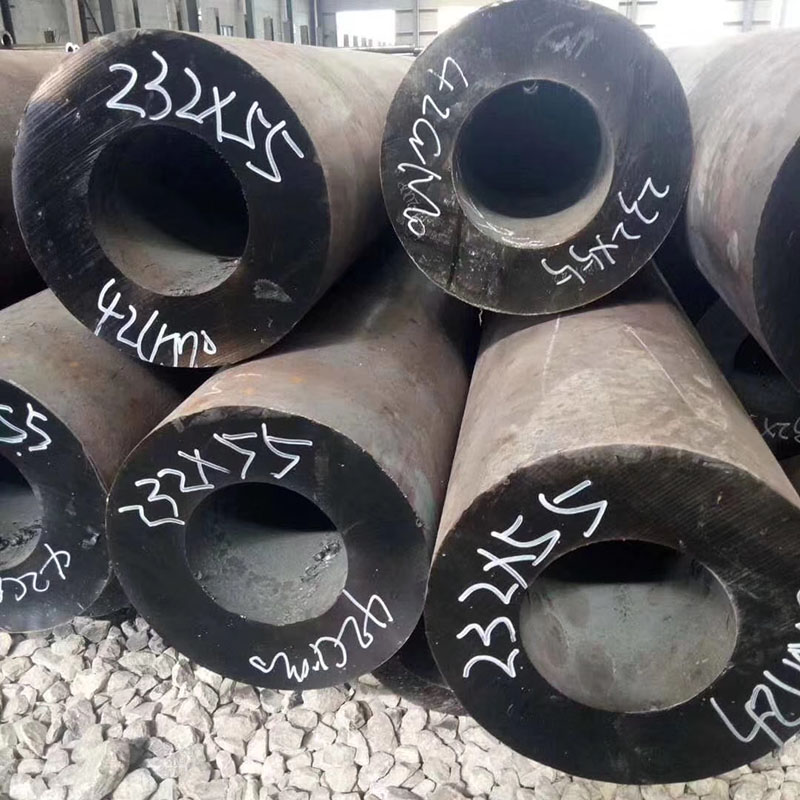

Wear resistant steel plate is composed of low carbon steel plate and alloy wear-resistant layer, which is generally 1 / 3 ~ 1 / 2 of the total thickness. The wear-resistant layer is mainly composed of chromium alloy, and other alloy components such as manganese, molybdenum, niobium and nickel are added. The carbides in the metallographic structure are distributed in fibrous form, and the fiber direction is perpendicular to the surface. The micro hardness of carbide can reach hv1700-2000 and the surface hardness can reach HRC58-62. The alloy carbide has strong stability at high temperature, high hardness and good oxidation resistance. It can be used normally within 500 ℃. Wear resistant steel plates are mainly divided into three types: universal type, impact resistant type and high temperature resistant type; The minimum thickness of wear-resistant steel plate can reach 5.5 (2.5 + 3) mm, and the maximum thickness can reach 30 (15 + 15) mm; Wear resistant steel plate can roll wear-resistant pipe with minimum diameter of DN200, and can be processed into wear-resistant elbow, wear-resistant tee and wear-resistant reducing pipe.

Product Parameter

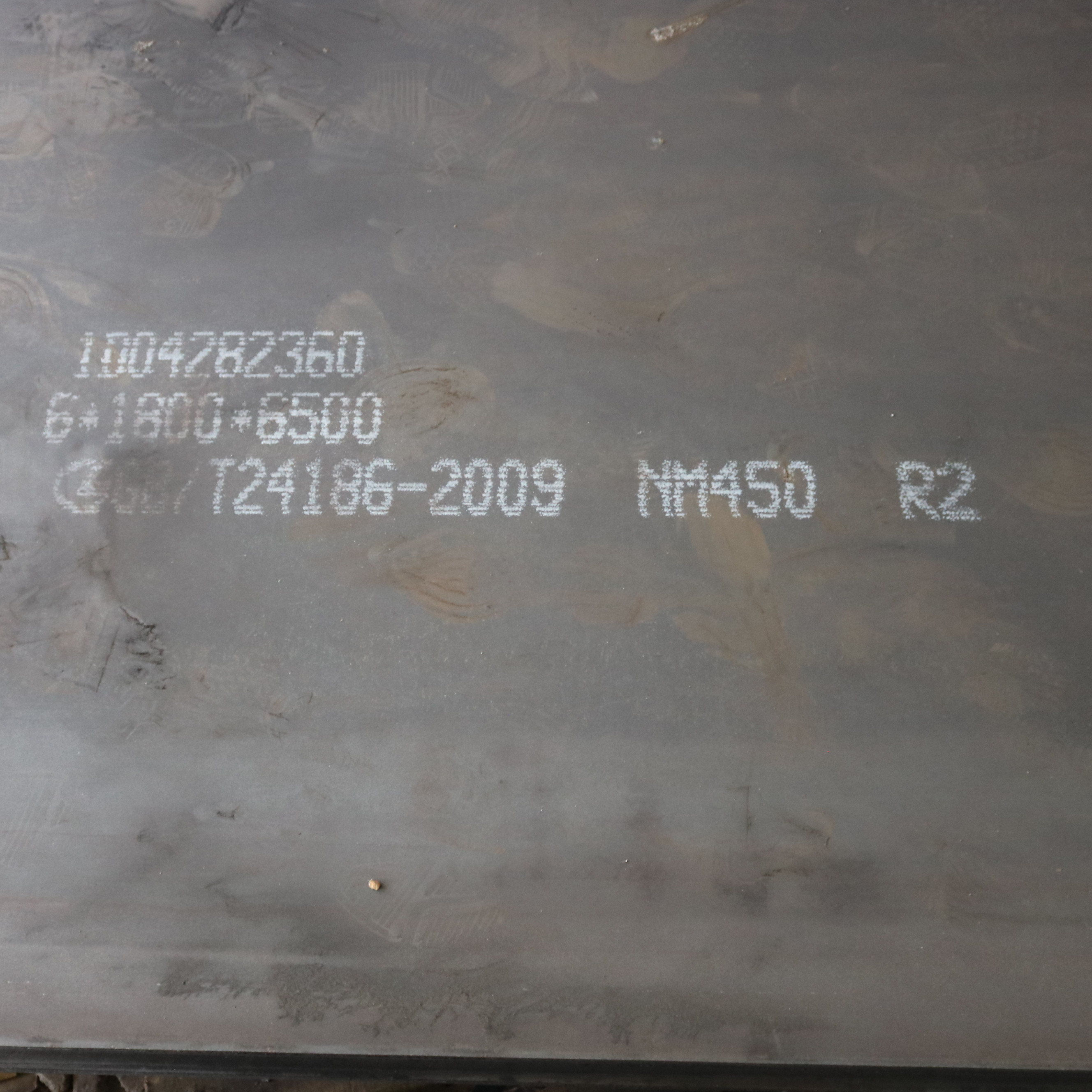

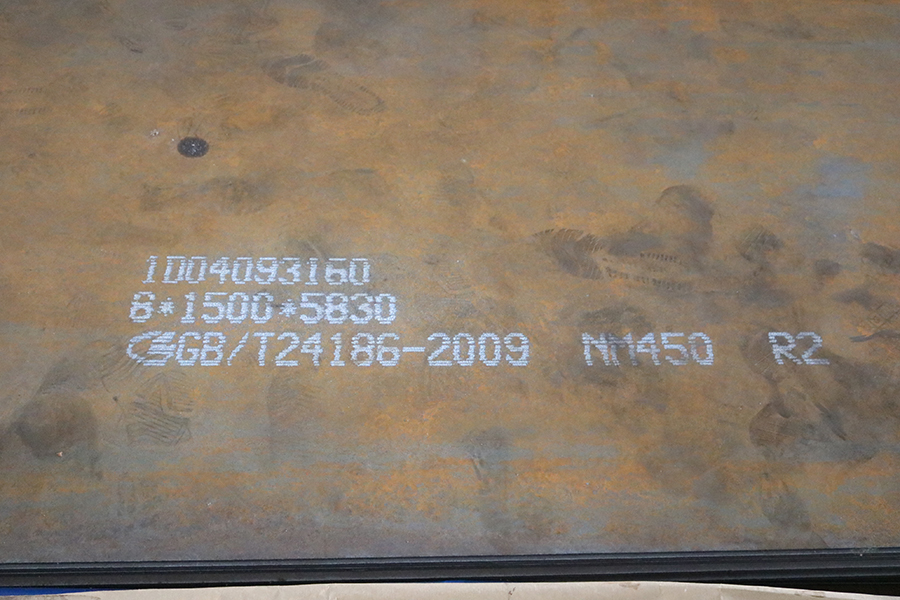

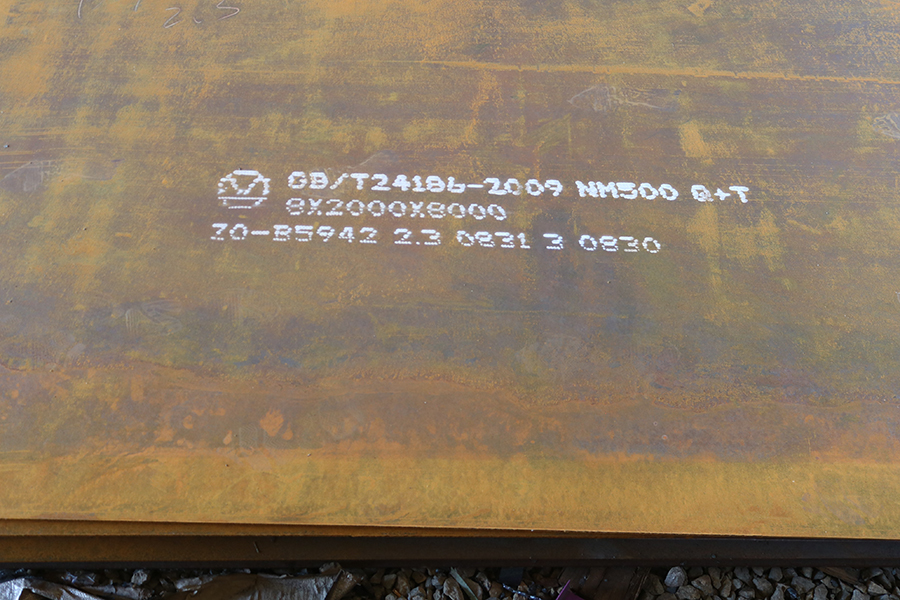

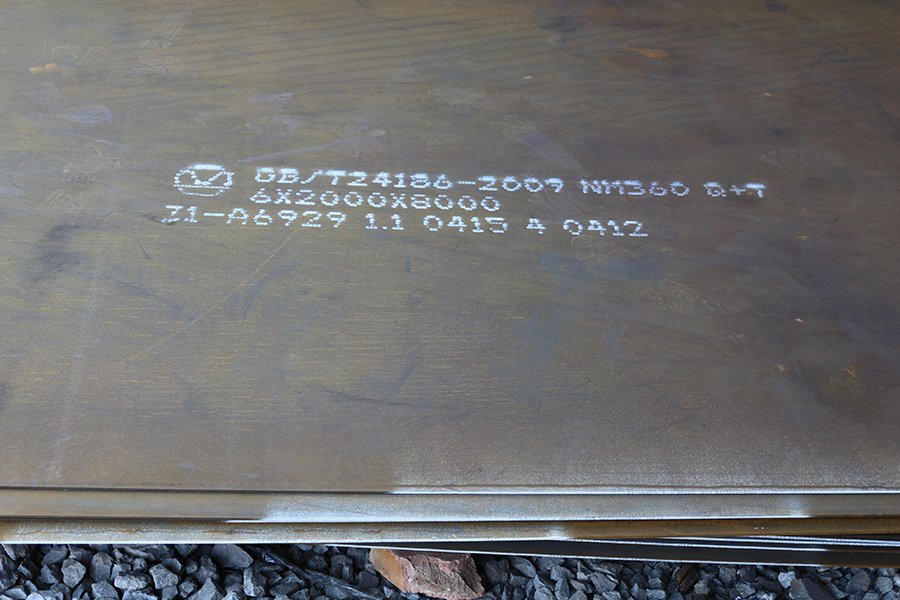

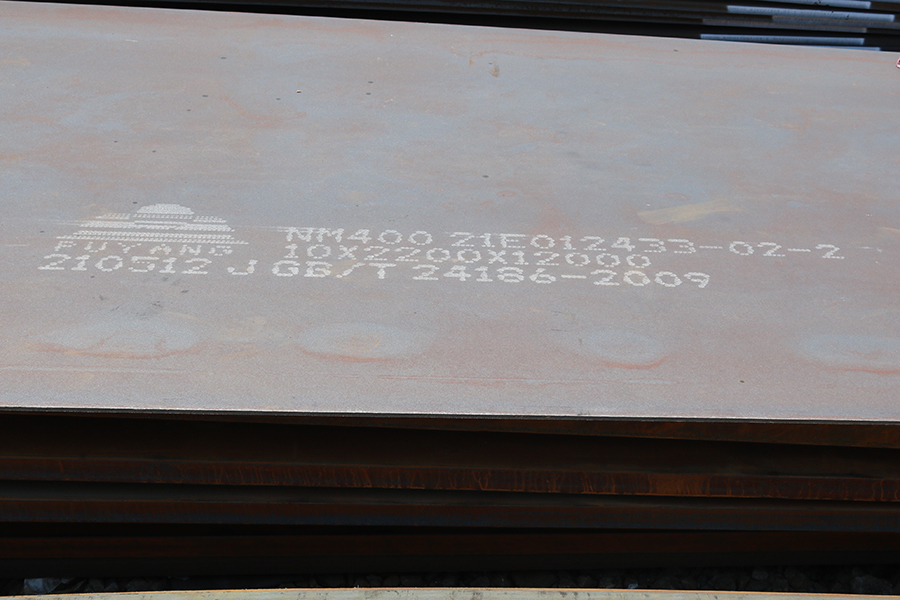

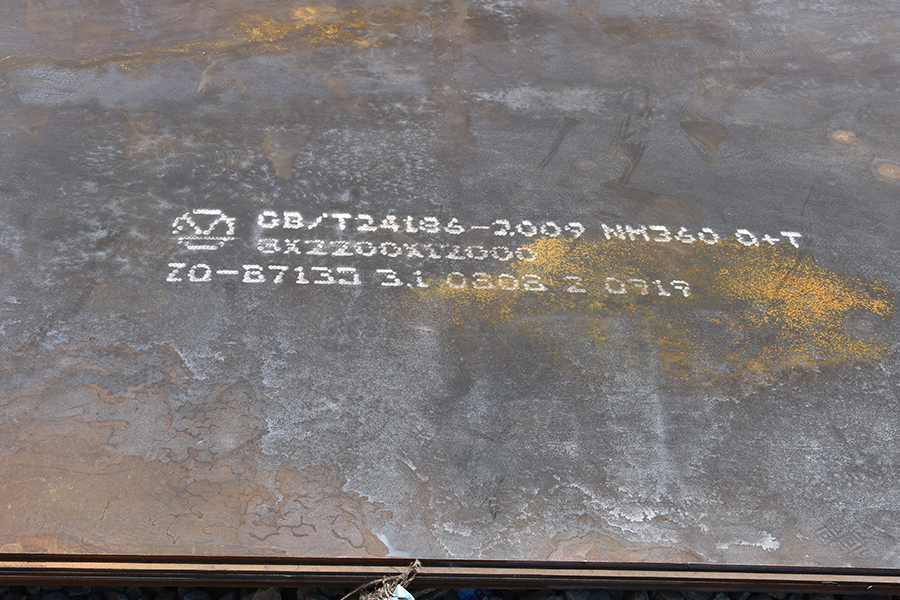

| Standerd | GB/T24186-2009 AISI, ASTM, BS, DIN, GB, JIS |

| Steel pipe grade | NM360 NM400 NM450 NM500 Mn15Cr1 Mn13 A36 SS400 Q235 Q345 S235 S355 |

| Length * width | Length:Customers’ Requirementwudth: 600-1500mm |

| Technique | hot rolled/cold rolled |

| Thickness(HRC) of wear resistant layer | The thickness of wear-resistant layer is less than 4mm: hrc54-58;Wear resistant layer thickness >4mm:hrc56-62 |

| Processing Service | Cutting or according to the customer’s demand |

| Packaging Details | Seaworthy export packing or as your requirement |

| Terms of Payment | T/T L/C |

| Port | Qingdao |

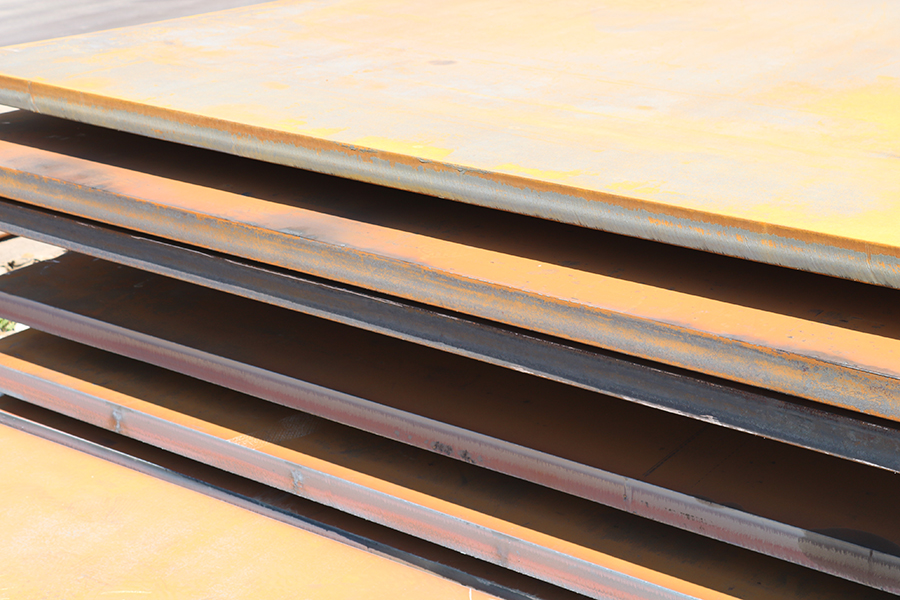

Product Show

Product Application

Wear resistant steel plate has high wear resistance and good impact performance. It can be cut, bent and welded. It can be connected with other structures by welding, plug welding and bolt connection. It is time-saving and convenient in the process of maintenance. It is widely used in metallurgy, coal, cement, electric power, glass, mining, building materials, brick and tile industries, Compared with other materials, it has high cost performance and has been favored by more and more industries and manufacturers.

Advantages

Our company has a large number of inventory, can meet your needs in time.

provide relevant information in time according to the customer’s demand to ensure the quantity and quality of products.

Relying on the country’s largest steel market, one-stop with all the products you need to save costs for you.

Processing Services

Production Process

Product detail pictures:

Related Product Guide:

Our company insists all along the quality policy of "product good quality is base of enterprise survival; buyer fulfillment will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" and also the consistent purpose of "reputation very first, shopper first" for 18 Years Factory Low Alloy Heat Resistant Steel Plate - Wear resistant steel plate / impact resistant plate / high temperature resistant plate for construction machine – Huayi, The product will supply to all over the world, such as: Amsterdam, Bahrain, United Arab Emirates, We will supply much better products with diversified designs and professional services. At the same time, welcome OEM, ODM orders, invite friends at home and abroad together common development and achieve win-win, integrity innovation, and expand business opportunities! If you have any question or need more information please feel free to contact us. We are looking forward to receiving your enquiries soon.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.