Seamless Alloy Steel Pipe 180*22 180*25 40cr Alloy Tube 4140 Alloy Structure Pipe

Product Description

40Cr belongs to medium carbon quenched and tempered steel and cold heading die steel. The steel has moderate price and easy processing. After proper heat treatment, it can obtain certain toughness, plasticity and wear resistance. Normalizing can promote the refinement of the structure, close to the equilibrium state, and improve the cutting performance of the blank. When tempered at 550 ~ 570 ℃, the steel has the best comprehensive mechanical properties. The hardenability of the steel is higher than that of 45 steel, which is suitable for surface hardening treatment such as high frequency quenching and flame quenching. 40Cr shaft part is one of the typical parts often encountered in machine. It is mainly used to support transmission parts, transfer torque and bear load.

Product Parameter

| Standerd | GB ASTM ISO JIS DIN |

| Steel pipe grade | 40cr 41Cr4 40X 5140 SCr440 530M40 |

| Lengh | 3-12m |

| Outer Diameter | 32-756mm |

| wall thickness | 2.5-100mm |

| Processing Service | Cutting or according to the customer's demand |

| Packaging Details | Bare packing/wooden case /waterproof cloth |

| Terms of Payment | T/T L/C at sight |

| 20 feet container contains dimension | Length under 6000mm |

| 40 feet container contains dimension | Length under 12000mm

|

| Samples | Free samples are provided but the freight is paid by the buyer |

| Min order | 1 Ton |

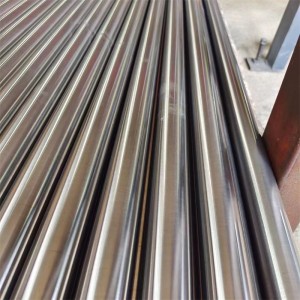

Product Show

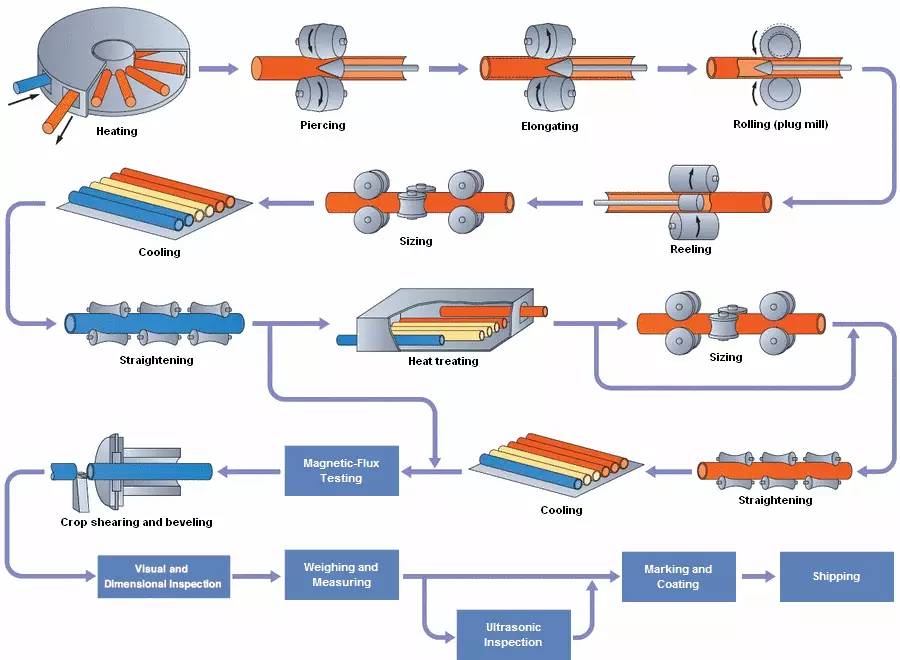

Processing services

Advantage

1,Our company has a large number of inventory, can meet your needs in time.

2, provide relevant information in time according to the customer's demand to ensure the quantity and quality of products.

3、Relying on the country's largest steel market, one-stop with all the products you need to save costs for you.

Chemical Composition

C:0.37~0.44 Si:0.17~0.37 Mn:0.50~0.80 Cr:0.80~1.10

Ni:≤0.30 P:≤0.035 S:≤0.035 Cu:≤0.030 Mo:≤0.10

Product Application

40Cr and other alloy structural steels are suitable for shaft parts with medium precision and high speed. After quenching, tempering and quenching, these steels have better comprehensive mechanical properties. After quenching and tempering, this kind of steel is used to make mechanical parts which can bear medium load and medium speed, such as steering knuckle, rear half shaft of automobile, gear, shaft, worm, spline shaft and top sleeve of machine tool.

Production Process