-

Seamless Alloy Steel Pipe 180*22 180*25 40cr Alloy Tube 4140 Alloy Structure Pipe

40Cr steel is one of the most widely used steels in machinery manufacturing industry. After quenching and tempering, it has good comprehensive mechanical properties, good low temperature impact toughness and low notch sensitivity. The hardenability of the steel is good, and it can be quenched to the maximum when water quenched Ф 28 ~ 60mm, oil quenched to Ф 15~40mm。 When the hardness is 174 ~ 229hb, the relative machinability is 60%. The steel is suitable for making medium plastic mould.

-

Seamless Casing Pipe Ibr Seamless Pipe Seamless Alloy Steel Pipe Alloy Steel Bar

40Cr steel is one of the most widely used steels in machinery manufacturing industry. After quenching and tempering, it has good comprehensive mechanical properties, good low temperature impact toughness and low notch sensitivity. The hardenability of the steel is good, and it can be quenched to the maximum when water quenched Ф 28 ~ 60mm, oil quenched to Ф 15~40mm。 When the hardness is 174 ~ 229hb, the relative machinability is 60%. The steel is suitable for making medium plastic mould.

-

Large Diameter Seamless Steel Pipe Alloy Seamless Steel Tube

40Cr steel is one of the most widely used steels in machinery manufacturing industry. After quenching and tempering, it has good comprehensive mechanical properties, good low temperature impact toughness and low notch sensitivity. The hardenability of the steel is good, and it can be quenched to the maximum when water quenched Ф 28 ~ 60mm, oil quenched to Ф 15~40mm。 When the hardness is 174 ~ 229hb, the relative machinability is 60%. The steel is suitable for making medium plastic mould.

-

Straight welded pipe ERW thin wall tube

Welded steel pipe, also known as welded pipe, is a steel pipe welded with steel plate or strip steel after crimping. Generally, the length is 6m. Welded steel pipe has the advantages of simple production process, high production efficiency, many varieties and specifications and less equipment investment, but its general strength is lower than that of seamless steel pipe. Welded pipes with large or thick diameter are generally made of steel blank directly, while small welded pipes and thin-walled welded pipes only need to be welded directly through steel strip.

-

P91 T91Alloy seamless steel tube high pressure boiler tube petroleum cracking tube

P91 seamless steel pipe has high high temperature strength, excellent oxidation resistance and good process performance. It is mainly used as pipeline or structural parts for conveying fluid, and has become an ideal steel for power station boiler.

-

Factory direct sales precision bright tube seamless steel pipe for machining standard tolerance

Precision steel pipe is a kind of high precision steel pipe material after cold drawing or hot rolling. Due to the advantages of no oxide layer on the inner and outer walls of precision steel pipe, no leakage under high pressure, high precision, high finish, no deformation during cold bending, no expansion, flattening and no crack, it is mainly used to produce pneumatic or hydraulic components, such as air cylinder or oil cylinder, which can be seamless pipe or welded pipe.

-

Precision bright tube 1020 s20c 1045 S45C gr.50 5120 5140 small tolerance

Precision steel pipe is a kind of high precision steel pipe material after cold drawing or hot rolling. Due to the advantages of no oxide layer on the inner and outer walls of precision steel pipe, no leakage under high pressure, high precision, high finish, no deformation during cold bending, no expansion, flattening and no crack, it is mainly used to produce pneumatic or hydraulic components, such as air cylinder or oil cylinder, which can be seamless pipe or welded pipe.

-

Alloy pipe seamless steel pipe for high pressure heat resistant alloy pipe and low pressure alloy pipe structure

Alloy pipes are divided into structural seamless pipes and high-pressure heat-resistant alloy pipes. It is mainly different from the production standard and industry of alloy pipe. Annealing and tempering of alloy pipe changes its mechanical properties. Meet the required processing conditions. Its performance is higher than that of ordinary seamless steel pipe, its utilization value is higher, the chemical composition of alloy pipe contains more Cr, and its performance of high temperature resistance, low temperature resistance and corrosion resistance. The common carbon seamless pipe does not contain alloy components or has few alloy components. The reason why alloy pipes are widely used in petroleum, aerospace, chemical industry, electric power, boiler, military industry and other industries is that the mechanical properties of alloy pipes change and are easy to adjust.

-

Thick wall seamless steel pipe for spare parts for boiler for fertilizer equipment

The production process of thick wall seamless steel pipe can be divided into four basic ways: cold drawing, cold rolling, hot rolling and hot expansion; Seamless steel pipe for conveying; Seamless steel pipe for boiler; High pressure seamless steel pipe for boiler; High pressure seamless steel pipe for chemical fertilizer equipment; Seamless steel pipe for geological drilling; Seamless steel pipe for oil drilling; Seamless steel pipe for petroleum cracking; Seamless steel pipes for ships; Cold drawn and cold rolled precision seamless steel pipe; All kinds of alloy tubes. Thick wall seamless steel pipe is mainly used for machining, coal mine, hydraulic steel, etc.

-

Thin-wall steel tube Geological drilling/Petroleum cracking steel pipe for boiler for fertilizer equipment

Thin walled seamless steel tube is made of steel ingot or solid tube blank by piercing, and then by hot rolling, cold rolling or cold drawing. Thin walled seamless steel pipe plays an important role in China’s steel pipe industry< φ 76%, accounting for 35%< φ 159-650, accounting for 25%.

-

Q345 ASTMGr.50 ISOE355CC JISSN400 low alloy high strength structural seamless steel pipe

Q345 seamless pipe belongs to low alloy series – low alloy high strength structural steel (GB / t1591-1994). Q345A, B, C, D and E are the representative grades of this kind of steel. Compared with carbon structural steel, Q345A has the advantages of high strength, good comprehensive performance, long service life, wide application range and relatively economic. It is widely used in bridges, ships, boilers, vehicles and important building structures.

-

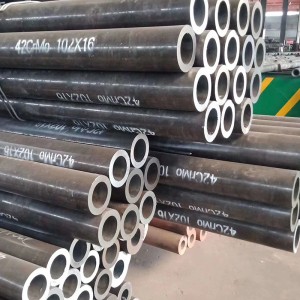

42crmo4 4140/4142 alloy seamless steel pipe wear-resisting steel tube

42CrMo steel belongs to alloy structural steel in terms of material classification. It has good mechanical properties and machinability, and is widely used. There are mainly two types of materials, plate and round bar. Its comprehensive performance is better than 40Cr, which has been recognized by the industry.

- Email daisy_sdhygg@163.com

- Phone 86-15863538780